At R G Loewenguth Co Inc, we're dedicated to increasing the effectiveness of your inspection systems through real world applications, with help from the top gage manufacturers in the world.

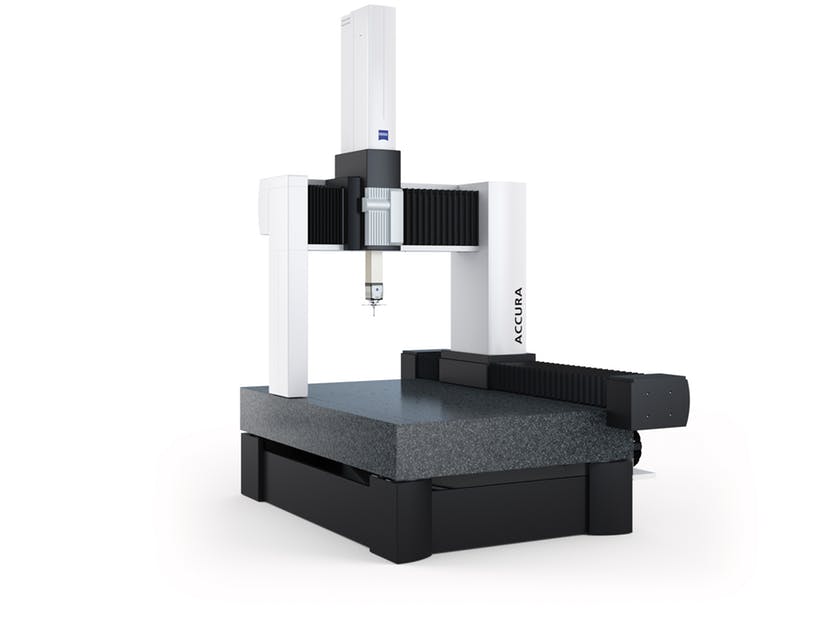

Carl Zeiss Industrial Metrology, LLC

Carl ZEISS IMT is a world leader in Industrial Measuring Technologies, and R.G. Loewenguth Co. is proud to be representing the ZEISS product line. For complete product details, click here to go to ZEISS's extensive web site. But be sure to check with us first for your best price and delivery.

OGP Contour Projectors

Certified Comparator Products offers a range of New and PreOwned optical comparators and profile projectors to help you control the quality of your manufacturing. Our New optical comparators combine the best in hardware, optics, illumination, and software to meet the needs of today's manufacturers. Our PreOwned comparators undergo an exhaustive service check, and are ready to serve as a cost-effective solution in your lab or manufacturing environment. We also have financing options available to help you with your optical comparator purchase.

Pratt & Whitney

Pratt & Whitney®, founded in 1860, is recognized as a supplier of high quality, high accuracy, calibration instruments. Pratt & Whitney incorporates laser and computer technology in its metrology products. These new products complement the company's already established electronic measuring instruments, SuperMicrometers.

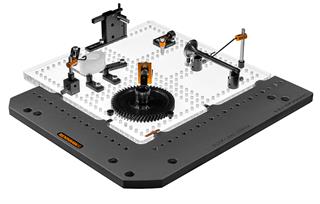

Glastonbury Southern Gage

Glastonbury Southern Gage Company is the largest manufacturer in the USA of thread gages (plug and ring), as well as cylindrical plug and ring gages, surveillance masters, thread wires, CMM and vision verification gages, and optical flats. In fact, they have the largest on-the-shelf stock of thread gages. Also, their line of Centerline Flex Plug Gages allow fast and accurate inspection of threaded hole locations with your coordinate measuring machine.

Prolink

In 1983 Prolink embarked on a mission to write a Statistical Process Control (SPC) software program called QC-CALC™ to interface with various automatic inspection equipment. The need for an easy to use data collection and analysis software was apparent.

Many other SPC packages perform the same analysis functions as QC-CALC, but none offer the automatic database creation that has been our cornerstone. We have listened to customer’s needs and tailored the software accordingly. Our goal is to increase our customer’s awareness of process problems to save them time and money. The key is to obtain the data without adding cost and to report the analysis in a timely manner.